Industrial effluent is the wastewater that comes from factories, plants, and processing units. It often contains dirt, oil, chemicals, metals, dyes, and other harmful substances. If this water is released into rivers or land without proper treatment, it can cause serious damage to the environment, animals, and people.

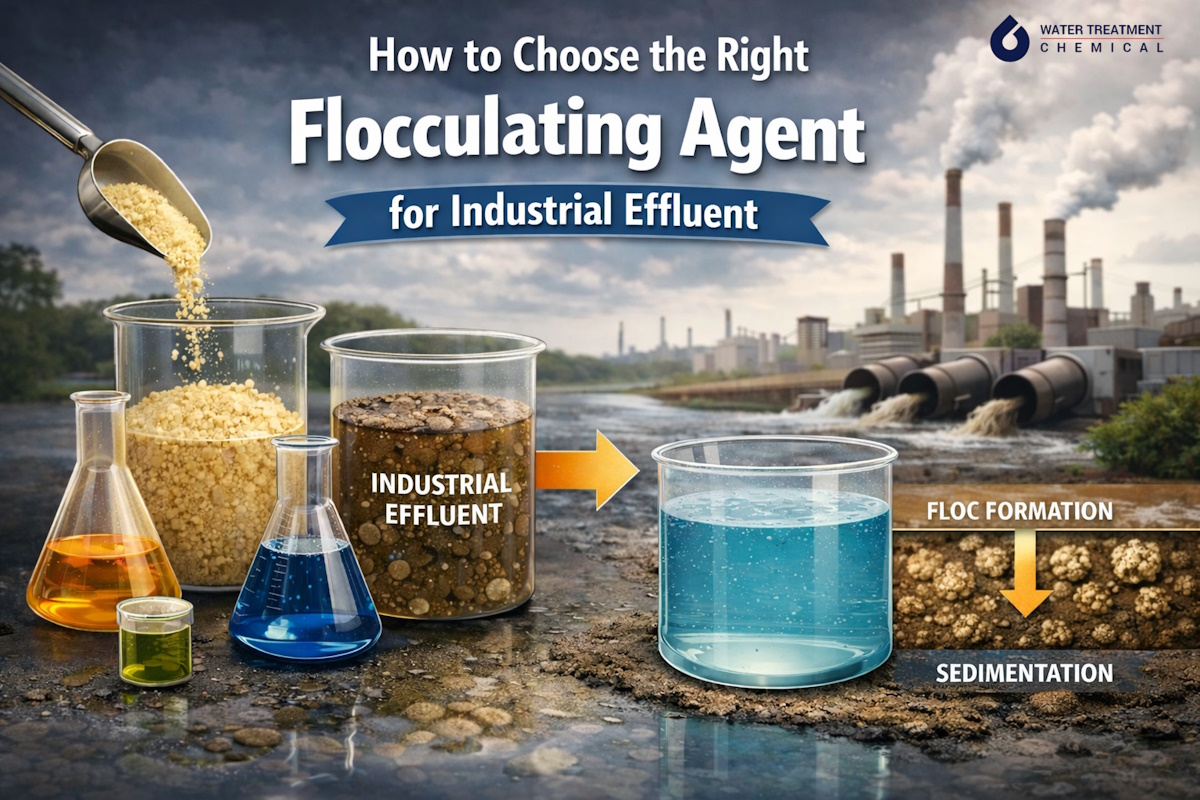

One of the most important steps in treating industrial wastewater is removing tiny solid particles that do not settle easily. This is where a Flocculating Agent becomes useful. These agents help small particles stick together and form larger clumps that can be removed easily. Choosing the right Flocculating Agent makes the water treatment process more effective, more affordable, and more safe for the environment.

This article explains what flocculating agents are, how they work, and how to select the best one for industrial effluent. It also explains the role of flocculating and deflocculating agents and how they fit into modern water treatment solutions.

Need better water clarity for your industrial effluent?

What Is a Flocculating Agent?

A Flocculating Agent is a chemical that helps small solid particles in water join together. These tiny particles are often so small that they stay suspended in water and do not settle on their own. When a Flocculating Agent is added, it causes these particles to form larger groups called flocs. These flocs become heavy and sink to the bottom, or they float to the top, making them easier to remove.

In industrial effluent, these small particles can include clay, dyes, oil droplets, metal salts, and organic waste. Without a proper Flocculating Agent, it would be very hard to separate these particles from water.

Why Flocculation Is Important in Industrial Effluent Treatment

Flocculation plays a major role in cleaning industrial wastewater. Many industries such as textile, paper, food processing, mining, and chemical plants produce wastewater with high levels of pollution. These pollutants must be removed before the water can be reused or released.

Here are some reasons why flocculation is important:

- It helps remove harmful solids

- It improves water clarity

- It makes filtration easier

- It reduces chemical and treatment costs

- It protects water bodies from pollution

Using the correct Flocculating Agent makes the entire water treatment process more reliable and efficient.

Difference Between Coagulation and Flocculation

Before choosing a Flocculating Agent, it is helpful to understand how coagulation and flocculation work together.

Coagulation is the first step. It uses chemicals to remove the charge from tiny particles. These particles normally repel each other, which keeps them apart in water. Coagulation reduces this repulsion.

Flocculation comes next. A Flocculating Agent is added to bring these neutral particles together. The agent forms bridges between them and creates larger flocs that can be removed.

Both steps are part of good water treatment solutions.

Types of Flocculating Agents

There are different types of Flocculating Agents used in industrial effluent treatment. Each type works best for certain types of wastewater.

1. Inorganic Flocculating Agents

These include chemicals like aluminum sulfate, ferric chloride, and lime. They are widely used because they are easy to get and low in cost.

They work well for removing suspended solids and some organic matter. However, they can produce large amounts of sludge, which must be handled carefully.

2. Organic Flocculating Agents

These are also called polymer based flocculants. They are long chain molecules that help connect small particles together.

They are very effective and need smaller doses compared to inorganic types. They also produce less sludge, which makes waste handling easier.

3. Natural Flocculating Agents

These come from plants or other natural sources. Examples include starch, chitosan, and certain plant gums.

They are safe for the environment and are often used in eco friendly water treatment solutions.

Finding it hard to choose the right Flocculating Agent?

What Are Flocculating and Deflocculating Agents

Flocculating and deflocculating agents are both used in water treatment, but they have opposite effects.

A Flocculating Agent helps particles come together. A deflocculating agent keeps particles apart. Deflocculating agents are used when you want to keep solids evenly spread in water, such as in paints, ceramics, or some industrial mixtures.

In wastewater treatment, flocculating agents are far more common because the goal is to remove particles from water. Still, knowing how flocculating and deflocculating agents work helps in selecting the right chemical process.

Understanding Your Industrial Effluent

Every industrial effluent is different. To choose the best Flocculating Agent, you must understand what is in the wastewater.

Some important factors to check include:

- Type of solids

- Particle size

- pH level

- Temperature

- Oil and grease content

- Metal concentration

- Organic matter

A water test can show these details. This helps in selecting a Flocculating Agent that will work well with the specific wastewater.

How pH Affects Flocculating Agents

The pH of water plays a big role in how well a Flocculating Agent works. Some flocculants work best in acidic water, while others work better in neutral or alkaline conditions.

If the pH is too high or too low, the flocculant may not work properly. In many water treatment solutions, pH is adjusted before adding a Flocculating Agent to get the best result.

Choosing the Right Flocculating Agent

Selecting the right Flocculating Agent involves many factors. There is no one size fits all solution.

1. Know Your Industry

Different industries create different types of wastewater.

- Textile plants often have dyes and fibers

- Food plants have fats and organic waste

- Mining industries have heavy metals

- Chemical factories have complex compounds

Each type of effluent needs a different Flocculating Agent.

2. Identify the Main Pollutants

Find out what you want to remove. It could be solids, oil, color, or metals. The best Flocculating Agent for solids may not be the best for oil.

3. Test Different Flocculants

Many water treatment solutions involve lab testing. Small samples of wastewater are mixed with different flocculants to see which one works best.

This helps find the most effective and lowest cost option.

4. Check Sludge Volume

Some Flocculating Agents produce more sludge than others. More sludge means higher disposal costs. A good flocculant creates compact and easy to remove sludge.

5. Consider Environmental Safety

Some chemicals can be harmful if not handled properly. Natural or low toxicity flocculants are better for eco friendly water treatment solutions.

Role of Polymer Based Flocculating Agents

Polymer based Flocculating Agents are now widely used in industrial effluent treatment. They work very well at low doses and form strong flocs.

They are available in different charges like positive, negative, and neutral. The right charge depends on the type of particles in the water.

These polymers are a key part of modern water treatment solutions.

How to Apply a Flocculating Agent

Using a Flocculating Agent correctly is just as important as choosing the right one.

- The agent should be mixed properly in water

- It should be added at the right point

- Mixing should be slow to allow floc formation

- Enough time should be given for settling

Poor application can reduce the effectiveness of even the best flocculant.

Common Mistakes to Avoid

Many industries make mistakes when using flocculants.

- Using too much chemical

- Not adjusting pH

- Poor mixing

- Using the wrong type

- Ignoring water testing

Avoiding these mistakes helps improve water quality and lower treatment costs.

Benefits of Using the Right Flocculating Agent

When the correct Flocculating Agent is used, industries can see many benefits.

- Cleaner water

- Lower chemical use

- Less sludge

- Better compliance with rules

- Lower overall cost

It also helps protect the environment and public health.

Future of Flocculating Agents in Water Treatment

The demand for better water treatment solutions is growing. New Flocculating Agents are being developed that work faster, use lower doses, and are safer for nature.

There is also more use of natural and biodegradable flocculants. These help reduce pollution and support green practices.

Final Thoughts

Choosing the right Flocculating Agent for industrial effluent is a very important decision. It affects how clean the water becomes, how much money is spent, and how safe the process is for the environment.

By understanding the nature of your wastewater, learning how flocculating and deflocculating agents work, and testing different options, you can find the best solution for your plant.

Good water treatment solutions not only meet legal rules but also help industries work in a responsible and sustainable way.

A well chosen Flocculating Agent turns dirty industrial water into a safer and cleaner resource for reuse or release, which benefits everyone.

Want cleaner and safer discharge water?