Water treatment is a very important process for many industries today. Clean water is needed for safety, production, and environmental protection. One of the most important steps in water treatment is flocculation. This process helps remove dirt, solids, and unwanted particles from water.

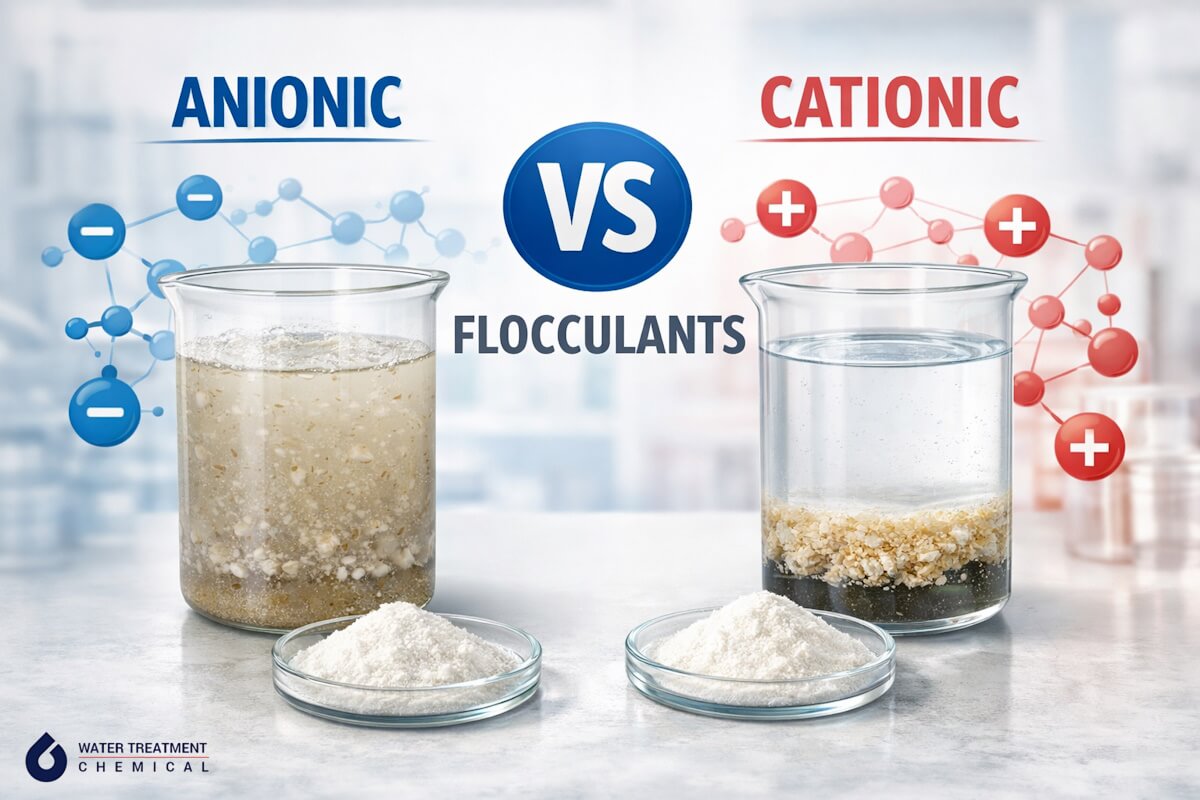

When choosing chemicals for this process, many plant managers face one big question: Anionic vs Cationic flocculants, which one should your plant use?

This article will explain everything in a simple and clear way. We will talk about how flocculants work, the differences between anionic and cationic types, where each one works best, and how to choose the right option for your plant. We will also cover common products such as Anionic PAM, Cationic PAM, and polyamines, and their role in flocculants for wastewater treatment.

Not sure which flocculant fits your process?

What Are Flocculants?

Flocculants are chemicals used to help small particles in water stick together. These particles are often too tiny to settle on their own. When flocculants are added, they help form larger groups called flocs. These flocs become heavy and settle at the bottom or float to the top so they can be removed.

Flocculants are widely used in:

- Wastewater treatment plants

- Drinking water treatment

- Mining and mineral processing

- Paper and pulp industries

- Textile and dye industries

- Food and beverage production

Without flocculants, separating solids from water would be slow and costly.

Why Flocculants Are Important in Wastewater Treatment

In wastewater treatment, the goal is to remove harmful materials before water is released back into nature or reused. These materials include:

- Suspended solids

- Organic waste

- Oils and grease

- Heavy metals

- Microorganisms

Flocculants for wastewater treatment help speed up this process. They reduce treatment time, improve water clarity, and help plants meet environmental rules.

Using the correct type of flocculant also reduces chemical use and lowers operating costs.

Understanding the Basics of Charge

To understand Anionic vs Cationic flocculants, you need to understand electric charge.

Most particles in wastewater carry an electrical charge. Usually, these particles are negatively charged. Because of this charge, they repel each other and stay suspended in water.

Flocculants work by neutralizing or bridging these charges so particles can come together.

There are three main types of flocculants based on charge:

- Anionic flocculants (negative charge)

- Cationic flocculants (positive charge)

- Non-ionic flocculants (no charge)

This article focuses on anionic and cationic types.

What Are Anionic Flocculants?

Anionic flocculants carry a negative electrical charge. They are often used when the particles in the water have a positive or neutral charge.

One of the most common types is Anionic PAM (polyacrylamide).

How Anionic Flocculants Work

Anionic flocculants work mainly through a process called bridging. The long polymer chains attach to particles and link them together into larger flocs.

They work best when:

- Water contains inorganic solids

- The pH is neutral to alkaline

- There are metal ions present

Common Uses of Anionic PAM

Anionic PAM is widely used in many industries, including:

- Mining and mineral processing

- Sand and gravel washing

- Paper and pulp production

- Municipal wastewater treatment

- Textile wastewater treatment

Anionic flocculants are especially useful when dealing with water that contains clay, sand, or other mineral particles.

Benefits of Anionic Flocculants

Some key advantages include:

- Strong floc formation

- Fast settling speed

- Works well in high solid content water

- Cost effective for large scale use

- Stable performance

These benefits make anionic flocculants a popular choice in many industrial applications.

Limitations of Anionic Flocculants

Even though they are very useful, they are not suitable for every situation.

Some limitations include:

- Not effective for negatively charged organic waste

- Performance can drop in low pH conditions

- May require careful dosage control

This is why understanding your wastewater composition is important before choosing a flocculant.

What Are Cationic Flocculants?

Cationic flocculants carry a positive electrical charge. They are commonly used when the particles in water are negatively charged.

A popular example is Cationic PAM, and another common group is Cationic PAM Polyamines.

How Cationic Flocculants Work

Cationic flocculants neutralize the negative charge of particles. This allows particles to come together and form strong flocs.

They are very effective in removing organic matter, sludge, and biological waste.

Common Uses of Cationic PAM and Polyamines

Cationic flocculants are widely used in:

- Municipal wastewater treatment

- Sludge dewatering

- Food processing plants

- Paper mills

- Chemical manufacturing

Cationic PAM Polyamines are especially effective when treating wastewater with high organic content.

Benefits of Cationic Flocculants

Some major advantages include:

- Excellent for organic waste removal

- Strong charge neutralization

- Fast settling and dewatering

- Works well in low dosage

Because of these benefits, cationic flocculants are often used in biological treatment systems.

Limitations of Cationic Flocculants

Like all chemicals, they also have limits:

- Can be more expensive than anionic types

- Overdosing can cause poor performance

- Sensitive to pH changes

- May create sticky sludge

Proper testing is important to get the best results.

Anionic vs Cationic: Key Differences

Below is a simple comparison to help you understand the difference between anionic vs cationic flocculants.

| Feature | Anionic Flocculants | Cationic Flocculants |

|---|---|---|

| Charge Type | Negative | Positive |

| Best For | Inorganic solids and mineral particles | Organic matter and sludge |

| Common Applications | Mining, sand washing, industrial water | Wastewater treatment, sludge dewatering |

| Cost | Usually lower | Usually higher |

| Performance | Strong floc formation | Strong charge neutralization |

Still deciding between Anionic vs Cationic flocculants?

How to Choose the Right Flocculant for Your Plant

Choosing the right product depends on several factors. There is no one size fits all solution.

1. Understand Your Wastewater

Test your wastewater to identify its pH level, type of solids, organic content, and temperature.

This information helps determine whether anionic or cationic flocculants will work best.

2. Identify the Charge of Particles

If particles are positively charged, use anionic flocculants, and if they are negatively charged, use cationic flocculants.

- Positively charged, use anionic flocculants

- Negatively charged, use cationic flocculants

This step is critical for proper treatment.

3. Consider Sludge Handling Needs

If your plant focuses on sludge dewatering, cationic flocculants are usually better.

If your plant deals with mineral solids, anionic flocculants may perform better.

4. Perform Jar Testing

Jar testing is a simple lab test used to compare flocculants and determine the best type, correct dosage, and settling speed.

This step can save time and money in full scale operations.

Role of Flocculants for Wastewater Treatment

Flocculants for wastewater treatment play a major role in protecting the environment. They help remove pollutants before water is released into rivers or reused.

Benefits include:

- Cleaner discharge water

- Lower treatment costs

- Reduced environmental impact

- Better compliance with regulations

Using the correct flocculant improves the entire treatment process.

Anionic PAM in Wastewater Treatment

Anionic PAM is often used in:

- Primary clarification

- Thickening processes

- Industrial wastewater systems

It works best when combined with coagulants like aluminum or iron salts.

Cationic PAM Polyamines in Wastewater Treatment

Cationic PAM Polyamines are widely used in:

- Sludge dewatering systems

- Biological treatment plants

- Activated sludge processes

They help bind organic matter and improve water clarity.

Environmental and Safety Considerations

When using flocculants, safety and environmental responsibility are important.

Key points to follow:

- Store chemicals in dry and cool areas

- Follow supplier handling instructions

- Avoid overuse to prevent water contamination

- Train staff properly

Modern flocculants are designed to be safe when used correctly.

Cost Considerations

Cost depends on several factors:

- Type of flocculant

- Required dosage

- Treatment volume

- Local availability

While cationic products may cost more, they often reduce overall treatment costs due to better performance.

Common Mistakes to Avoid

Some common mistakes include:

- Choosing flocculants without testing

- Using incorrect dosage

- Ignoring pH levels

- Mixing incompatible chemicals

Avoiding these mistakes ensures better results and lower costs.

Future Trends in Flocculant Technology

The flocculant industry is evolving. New developments include:

- Eco friendly polymers

- Higher efficiency products

- Lower dosage requirements

- Improved biodegradability

These innovations help make wastewater treatment more sustainable.

Final Thoughts: Anionic vs Cationic Flocculants

When comparing Anionic vs Cationic flocculants, there is no universal answer. The right choice depends on your wastewater type, treatment goals, and operational needs.

- Choose Anionic PAM for mineral rich and inorganic wastewater.

- Choose Cationic PAM Polyamines for organic rich wastewater and sludge treatment.

Both types play a vital role in modern water treatment systems. Understanding their differences allows your plant to operate more efficiently and responsibly.

Conclusion

Choosing the right flocculant is a critical decision for any water treatment plant. By understanding the differences between anionic and cationic flocculants, you can improve efficiency, reduce costs, and protect the environment.

Flocculants for wastewater treatment are essential tools in modern industry. With the right knowledge and proper testing, your plant can achieve better results and long term success.

If you need help selecting the right product, always consult a water treatment expert or supplier who understands your specific application.

Ready to choose the right flocculant for your plant?